🌟 Daily Awakening Quiz 🌟

Vibrations are an intrinsic part of our daily lives, yet they often go unnoticed until they cause issues like machinery failure or structural damage. The study of vibrations involves understanding the oscillatory motion of objects and how they interact within various environments. Whether you’re an engineer, a maintenance technician, or simply curious about how things work, gaining a clear grasp of vibrations can unlock insights into system performance, safety, and design optimization. In this article, we will explore the fundamental concepts of vibrations, their practical applications, and how understanding vibrations can help prevent costly failures.

What Are Vibrations?

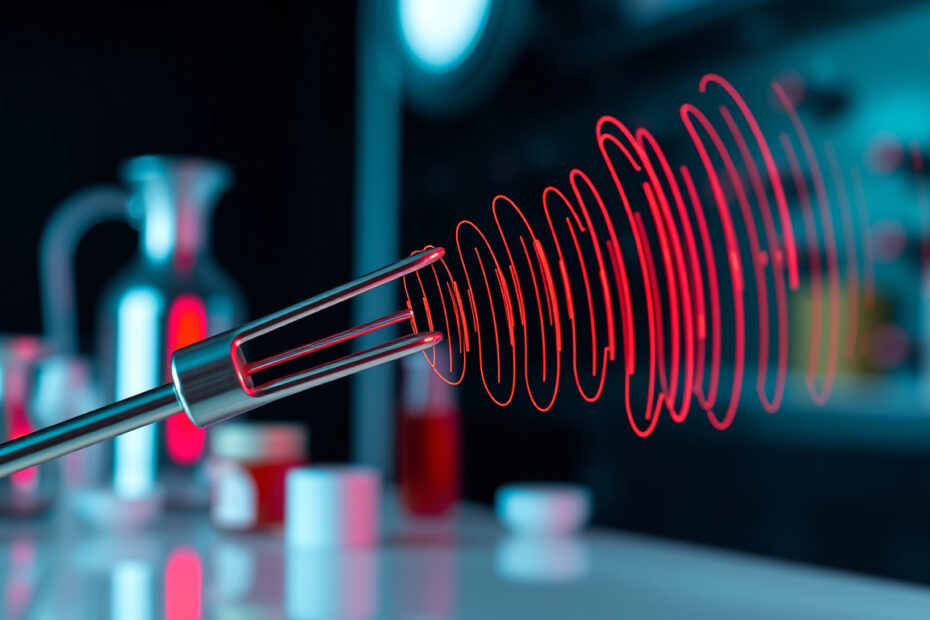

At its core, vibrations refer to the oscillating motion of an object around an equilibrium position. These oscillations can be caused by various forces—external impacts, imbalances, or internal forces—which induce periodic motion. Vibrations can be categorized based on their frequency, amplitude, and damping characteristics, influencing how they affect the systems involved.

Types of Vibrations

-

Free Vibrations: Occur when an object is displaced from its equilibrium position and allowed to oscillate without continuous external forces. Examples include a plucked guitar string or a swinging pendulum.

-

Forced Vibrations: Happen when an external force continuously drives the system at a specific frequency. For example, a car engine causing vibrations in the chassis during operation.

-

Damped Vibrations: Involve gradual reduction in amplitude over time due to energy dissipation, such as vibrations in a building with shock absorbers.

Understanding these basic types helps engineers design systems that can endure or mitigate vibrations efficiently.

Fundamental Concepts of Vibrations

1. Natural Frequency

Every physical system has a natural frequency, the rate at which it tends to oscillate when disturbed. When external vibrations match this frequency, resonance occurs—a phenomenon that can amplify vibrations dramatically, sometimes leading to catastrophic failures (like the infamous Tacoma Narrows Bridge collapse).

2. Amplitude and Damping

-

Amplitude measures the maximum displacement during oscillation. Higher amplitudes often translate to greater stress or wear.

-

Damping refers to mechanisms that reduce vibratory energy over time, limiting amplitude. Damping can be intrinsic (material-based) or added via damping devices like shock absorbers.

3. Vibration Modes

Systems can vibrate in different modes, each with a specific shape and frequency. Analyzing these modes helps in optimizing design to prevent failure.

Practical Applications of Vibrations

Understanding vibrations isn’t just academic; it plays a critical role across diverse industries and disciplines. Here are some key applications:

Structural Engineering

Engineers analyze vibrations to ensure buildings, bridges, and dams can withstand environmental forces like wind, earthquakes, and traffic loads. By modeling vibrational behavior, they can install dampers or design structural features to minimize resonance effects.

Mechanical and Automotive Engineering

Vibrations influence the longevity and performance of engines, turbines, and other machinery. Vibration analysis helps detect imbalances, misalignments, or worn components, enabling predictive maintenance and enhancing durability.

Aerospace Industry

Aircraft and spacecraft are subjected to complex vibrational loads. Understanding vibrations allows engineers to develop resilient structures, improve comfort, and ensure safety during high-stress operations.

Electronics and Instrumentation

In sensitive electronic devices, vibrations can affect data accuracy or cause malfunction. Vibration isolation and damping techniques are employed to safeguard performance.

Manufacturing and Quality Control

Vibration analysis can detect defects in manufacturing processes, such as imbalances in rotating machinery, leading to corrective actions that improve product quality.

Techniques for Analyzing Vibrations

A variety of tools and methods exist for analyzing vibrations in real-world systems:

- Accelerometers: Sensors that measure acceleration due to vibrations, providing data for analysis.

- Spectral Analysis: Techniques like Fast Fourier Transform (FFT) help identify dominant frequencies and vibration signatures.

- Modal Analysis: Determines the natural modes and frequencies of structures or machines.

- Vibration Testing: Simulating operational conditions to assess how systems respond under expected loads.

Harnessing these methods enables engineers to preemptively address potential issues, ensuring safety and performance.

Tips for Managing Vibrations Effectively

To optimize system performance and prolong lifespan, consider the following:

- Regular Monitoring: Use sensors to track vibrations over time and detect anomalies early.

- Design for Damping: Integrate damping elements like rubber mounts or tuned mass dampers.

- Balance Rotating Parts: Keep rotating machinery properly balanced to avoid excessive vibrations.

- Isolate Sensitive Equipment: Employ vibration isolators to prevent vibrations from affecting delicate instruments.

- Material Selection: Use materials with appropriate properties to minimize vibrational impact.

Frequently Asked Questions About Vibrations

Q1: How do vibrations affect machinery lifespan?

Vibrations can lead to fatigue, wear, and eventual failure if not managed properly. Excessive vibrational forces introduce stress concentrations, which over time deteriorate materials and components.

Q2: Can vibrations be completely eliminated?

While it’s challenging to eliminate vibrations entirely, engineers strive to minimize and control them through design improvements, damping, and isolation techniques.

Q3: What role does resonance play in vibrations?

Resonance occurs when a system’s excitation frequency matches its natural frequency, amplifying vibrations significantly. Avoiding operational conditions that induce resonance is critical for maintaining system integrity.

External Resource for Further Reading

To deepen your understanding of vibrations, you can consult “Mechanical Vibrations” by Singiresu S. Rao, a comprehensive textbook regarded as an authoritative resource in the field. Additionally, the NASA Technical Reports Server offers detailed research papers on vibration analysis in aerospace engineering (source).

Conclusion: Harnessing Knowledge of Vibrations for Better Designs

Vibrations are a vital aspect of engineering and environmental systems that, when understood and managed properly, can enhance safety, durability, and performance. Recognizing how vibrations behave, their causes, and how to mitigate their adverse effects empowers engineers and technicians to design resilient systems. Whether it’s preventing structural failure, extending machinery life, or improving comfort, understanding vibrations is key to innovation and safety.

Don’t wait until vibrations become a problem—start integrating vibration analysis into your design, maintenance, and quality assurance processes today. Embrace this knowledge to build stronger, safer, and more efficient systems for the future!